machining surface finish grades

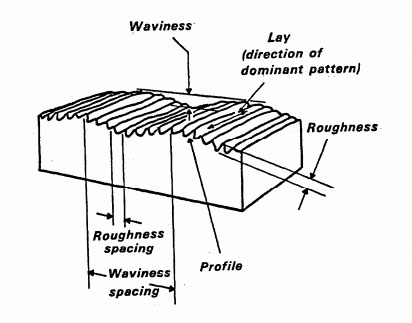

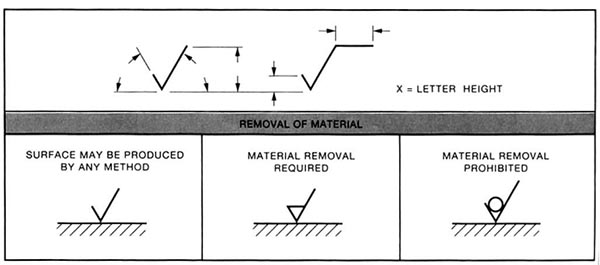

There are three parameters that distinguish a surface finish lay roughness and waviness. It is a measure of the complete texture of a products surface that is defined by.

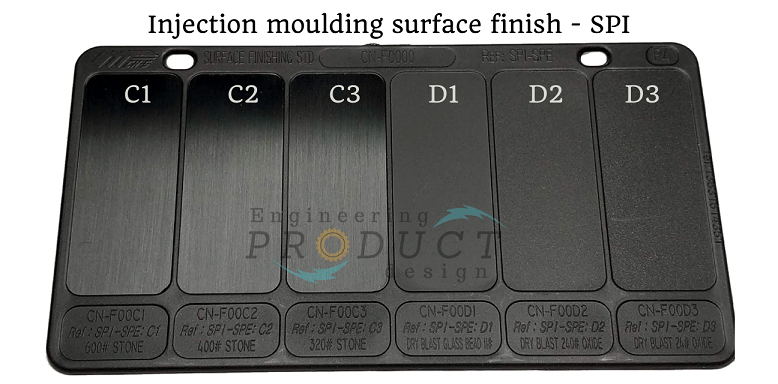

Injection Moulding Surface Finish Design Guide Design For Manufacture

Each of these parameters can be classified in terms of the geometrical shape of the surface.

. Ad For Precise Machining and Remarkable Surface Finish. There are 3 main ways to acquire the surface roughness value. N1 1 0025 Lapping.

Surface finish refers to the process of altering a metals surface that involves removing adding or reshaping. However other less sensitive industries or application areas may not require such fine finishing. Surface finish Also called sometimes surface roughness is a numeric representation of a surfaces smoothness.

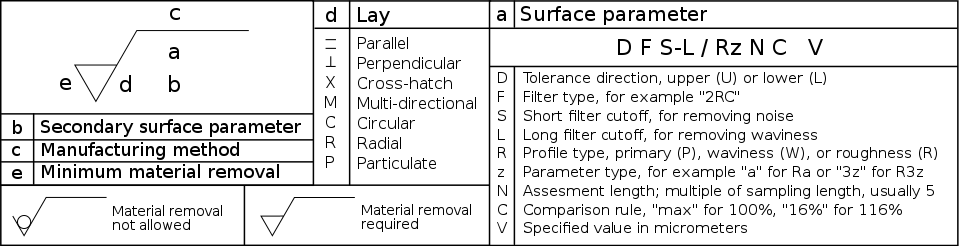

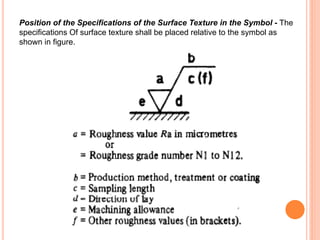

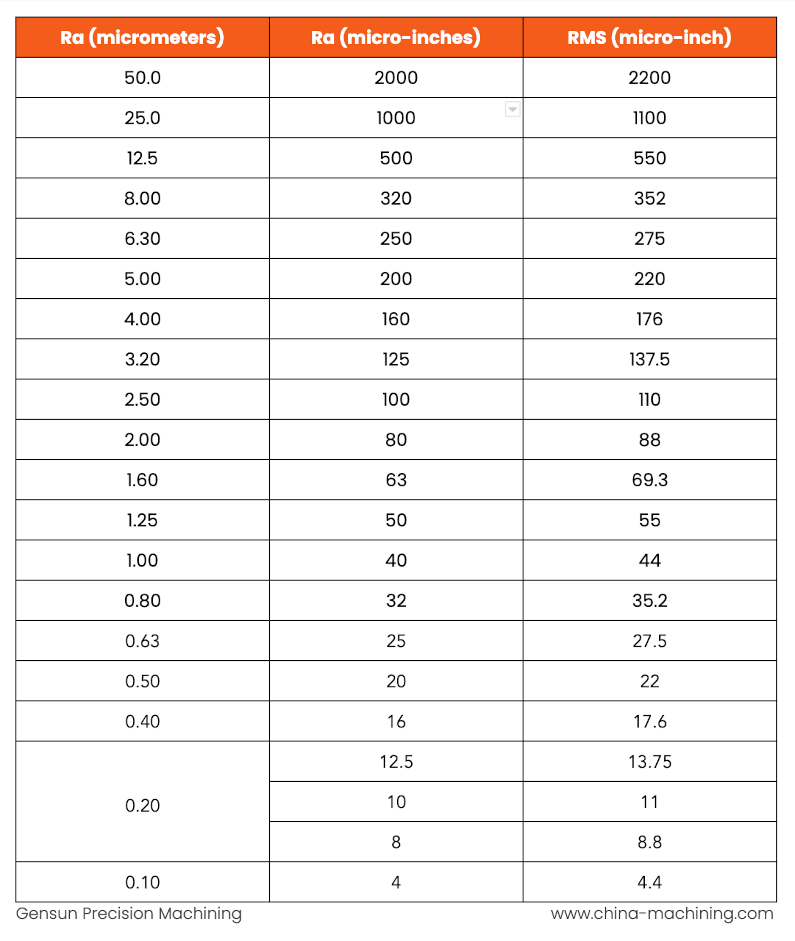

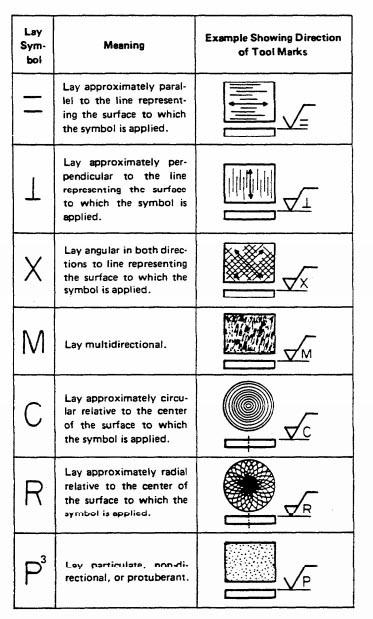

This can improve the resistance of the steel parts to corrosion and. Machining symbols and Surface finish Surface roughness number Ra is expressed in microns. Ra h1h2-----hnn The measurements are usually made along a.

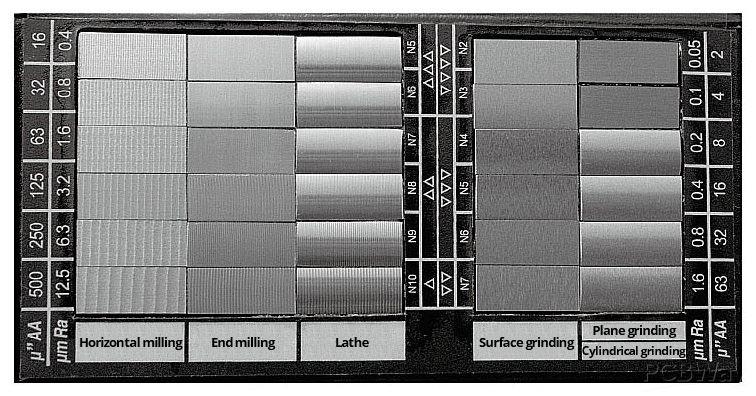

At Xometry Europe we offer four surface roughness levels that are also the values typically specified for CNC Machining applications. Machining N9 250 63 N10 500 125 Rough. Surface Roughness Grade Numbers Here is a chart shows how roughness grade numbers convert to Ra values and roughness symbols.

It is a means of altering material surfaces through processes involving adding. Surface finish specification and comparison. This surface finish involves electroplating steel metal by adding a thin layer of nickel around 01 mm.

If a surface is a bead blasted or if a piece of metal is spark eroded using EDM solid-sink to make a spark finish then you end up with a stippled surface. As Machined parts have minor visible tool marks. For instance medical-grade and optical instruments require the finest surface finishing.

Finish Symbol N Finish R a μinch R a μm Super finishing. There are a total of 12 grades of surface finishes and those grades are grouped into 4 categories. Surface Roughness Grades.

Machining surface finish grades Sunday June 5 2022 Edit. Surface finish requirements can be increased to 16 08 and 04 μm. The nature of a surface is known as surface finish or surface topography.

It refers to a surfaces minor local deviations from a perfectly flat surface an actual plane. Surface finishes are applied after machining and can change the appearance surface roughness hardness and. Surface finish is a parameter that determines the physical characteristics appearance of a component.

Machining Surface Finish Chart Conversion Comparator Method Degree Ra Rz Rms

Surface Roughness Explained Get It Made

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish Surface Roughness It S Indications Symbols

5 Grinding Considerations For Improving Surface Finish Norton Abrasives

Surface Finish Surface Roughness Symbols Charts Callouts Costs

Understand The Surface Roughness Chart And Make Great Parts

The Basics Of Surface Finish Gd T Basics

Surface Finish Gauges Testers Comparators Comparison Specimens Rubert Co Ltd

What Are The Types Of Surface Finishes For Cnc Machining Hubs

Stainless Steel Finishes Explained En Astm Fractory

Complete Surface Finish Chart Symbols Roughness Conversion Tables